Modern motorcycles are nothing short of amazing. Traction control, slipper clutches, variable valve timing; bikes have become so good their power and performance seem to be limited primarily by legislation. EPA/Environmental laws that dictate how much “stuff” is allowed out of the exhaust pipe, in the form of noise, CO, CO 2, soot or hydrocarbons become the limiting factors to what your bike can do. As a result, most every modern motorcycle comes with a catalytic converter and most every modern motorcycle suffers from a severe lean spot around 3,000 rpm, as that’s where the EPA tests engines for emissions.

To meet modern EPA standards, the goal is to completely burn all the fuel for a given amount of oxygen, and yes, the amount of oxygen changes based on temperature, elevation, humidity even your air filter and exhaust system have an effect on available oxygen. Most motors will produce the most power somewhere between 14.7 parts air to 1 part fuel to 12.5 to 1. This is the biggest advantage of fuel injection with O2 sensors that can “sniff” the exhaust and make adjustments to the fuel mixture to accommodate changes in available oxygen as well as a myriad of other conditions, but in order to ensure all the fuel is burned, manufacturers often choose to run an engine lean – more air for a given amount of fuel – to keep the exhaust as clean as possible.

Several companies are selling fuel injection systems that promise power gains and improved drivability with prices ranging from $400 to well over $1000. One of the more affordable and well-known products comes from a company that’s been on the motorcycle scene longer than liquid cooling.

Based in Nevada and Montana, DynoJet is a fully American and privately held company that began making “Jet Kits” in 1972 for older carbureted motorcycles and as the world transitioned to fuel injection so did Dynojet. They pretty much started the craze of making electronic modules that plug into the motorcycle’s main computer to alter air/fuel ratios.

Our Ducati 848 suffered from the standard lean-spot around 3,000 rpm causing engine surging and lurching during any kind of leisurely pace. It was bothersome, but our real problem was at higher rpm’s when we’d ease off the throttle to enter into a turn, the bike would hiccup and stumble when the engine starved for fuel. Judicious throttle control helped, but we really believed the performance could be made better. Which got us thinking; could the most affordable fuel injection system out there improve our bike?

Since the bike in question is a Ducati, the ECU cannot be reprogrammed below 5250 rpm’s and 20 percent throttle unless we upgraded to the very expensive Ducati Performance ECU. Since our goal was to improve the running of our little 848 for the least amount of money, the DynoJet Power Commander V, and its retail price of $399, was the most affordable option.

When we contacted DynoJet and asked some questions about the inability to tune below 5250rpm, they told us about a new little device they’d just released called the Optimizer. Once plugged in, this dongle interprets the signal from the closed loop oxygen sensor “tricking” the ECU to richen the air/fuel mixture to the optimum ratios. We thought there’d be no way this could really work, particularly with a retail price less than $100, but based on Dynojet’s reputation and their reassurance we had them throw one into our order.

When we received and opened the package we were really impressed by how far DynoJet has come. The new Power Commander V is absolutely diminutive; about the size of a pack of cigarettes. This is a big change from the PC’s of yesteryear that were closer to the size of a small goat.

Installation

We’ll avoid going into too much detail regarding installation since this will vary based on your motorcycle; that and DynoJets bike-specific instructions are very good. But we will say that getting the Power Commander V (PCV) onto the bike was a bit more involved than we expected it to be. We really thought it would be a 20-minute process of finding the correct plugs. But in order for fuel injection modules to work, they must have direct communication with the actual fuel injectors. This meant digging down into the bike far enough to access the fuel injection system.

For us, installation meant removing the body panels, the fuel tank and half of the air-box. The rear injector was a snap, but the front proved to be the most difficult and time-consuming because of how little space there is available to access the front injector. Squeezing between the frame spars and dealing with short wiring loom cables resulted in almost two hours of fiddling and ended with a matching set of bloody knuckles.

Once the cabling was all connected we struggled with finding a suitable mounting point for the actual module. Since our bike spends half of its life wearing race bodywork we couldn’t use DynoJet’s recommended placement forcing us to find an alternative home for the small, electronic box. DynoJet says the device is fully waterproof, but like any electrical component, we wanted to be smart and place things in a location that would minimize exposure to moisture.

The Optimizer was a much simpler ordeal; more of what we originally expected. We found the correct plug, interjected the Optimizer and we were ready to roll, although our concerns about potential moisture were heightened by the uncomplicated nature of the device and its simple casing.

Dyno Time

The next step was to get the bike tuned, which required a trip to our nearest dynamometer. Ours is at Moto Station who employs one of the best Dyno-Tune Technicians we’ve ever worked with. With Salt Lake Motorsports at the controls, we were confident of getting good results. The Power Commander still comes with the necessary software and cabling to tune the motorcycle yourself by employing a USB cable and a laptop, but we really wanted to trust our engines management to someone who actually knew what they were doing.

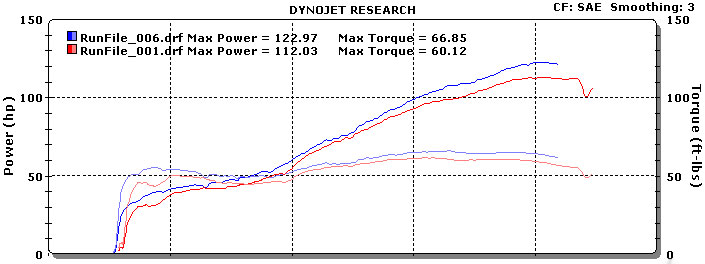

So, first things first, we hooked the bike up and did some initial runs to see where we were starting. As expected the bike was off-the-charts lean around 3,000 rpm, skyrocketing into 18:1 range, (18 parts air to 1 part fuel) which is about 60% leaner than it should be, resulting in a max of 112hp and 60 ft.lbs of torque.

With our baseline established, Roy began tuning. When the PCV is connected to an actual DynoJet dynamometer, tuning goes much faster as each run is recorded, the optimum difference in fueling identified and new values automatically inserted into the PCV. This is much better than the old days were each individual run was recorded and the tech had to go through and manually enter the new values. With the new PCV the tech still has the option to over-ride suggested values if they identify any special needs. The best part of this new tuning system is that it reduces the number of required dyno-runs. This means less wear on the motor and tires and fewer hours of dyno-time that you’ll need to pay for.

During each run, we kept a close eye on the air/fuel ratios below 5250 rpm to see if the Optimizer was actually doing anything. At first, it didn’t look like it did a thing but after each run, we could see the air/fuel ratio’s gradually richened to more appropriate values. By the end of our dyno-time, the air/fuel mixture below 5250rpm was hovering right around 13.8:1. Pretty gosh-darn perfect.

Dynojet offers an additional module called the “AutoTune” ($259) that maintains continual communication with the Power Commander V and makes constant adjustments to the air/fuel ratio’s, just like the dynamometer does. We think this is a brilliant solution for anyone who does not have easy access to a Dyno.

Results

Although we were much more interested in achieving optimum air/fuel ratio’s and eliminating the lean lurching and stumbling, our horsepower numbers increased drastically from 112.03 to 122.97 hp and from 60.12 to 66.85 torques, more than a 10% gain. That’s cheap horsepower! For comparison, another Salt Lake Motorsports customer who races an 848, has invested in lots of motor upgrades as well as one of the other tuning modules that cost more than double that of the DynoJet, produces roughly 0.5hp more than our stock bike.

Increases in hp numbers are great for bragging rights, but it’s hard to “feel” the difference between 112 and 123 while chasing down your favorite canyons, but what we did notice was significant enhancements in overall performance. We were even able to decrease our lap times a smidgen, something we attribute more to the improvements in throttle transitions than overall hp gains; and what’s more, the disappearance of throttle snatchiness is felt every time the motorcycle is underway.

Summary

We knew that the Power Commander was going to help to the bike, but we never guessed the changes would be as dramatic as they were. And even with those significant improvements, the real winner of this story still has to be the humble Optimizer. If you own a Ducati, for less than $100 you can make a noticeable improvement to how the bike runs – all without even needing any Dyno-Time! Overall, we couldn’t be any happier with our end result. DynoJet may offer one of the more affordable systems on the market, but in this case, lower cost does not mean you are getting less performance.

For more information, including bike-specific applications, be sure to check out DynoJet.com / PowerCommander.com.